The water pump system for the building is one of the important factors. Depending on the characteristics and scale of each project, select and install a suitable pump system.

The pump system has a high-sensitivity pressure sensor mounted on the pipeline to detect pressure changes when there is a change in water consumption. The above signal is transmitted to the inverter to change the new frequency to the rotor speed controller. As a result, it is possible to add or remove pumping equipment in the system to stabilize the water pressure on the pipeline according to the requirements of users in the building.

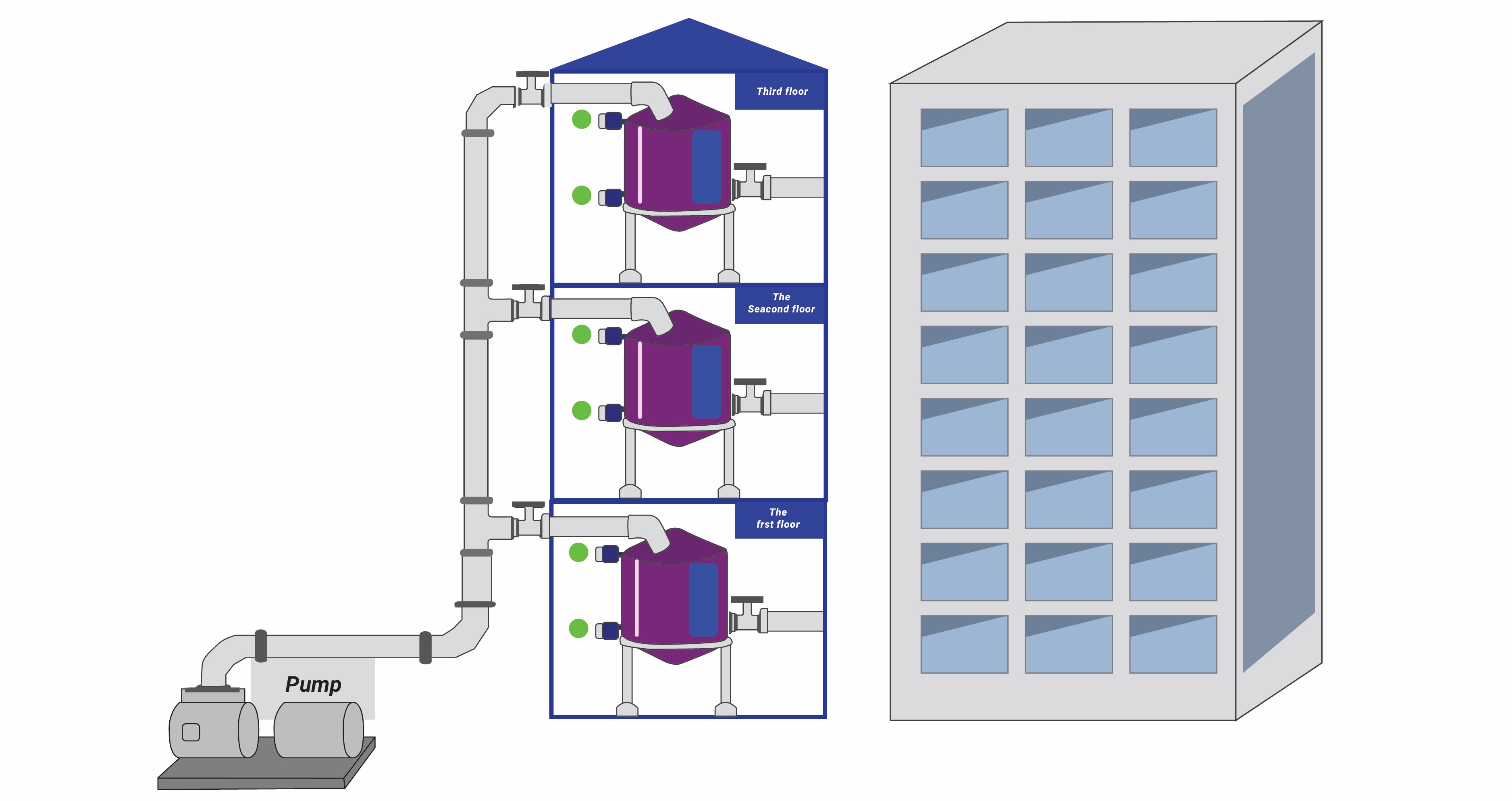

The working diagram of the water pump system

The pressure sensor is located on the main water supply pipe. It will transmit a signal to the inverter when there is a change in pressure in the pipeline. At this time, the signal of inverter is compared with the preset pressure value. The inverter relies on the pickup comparison results to control the power supply frequency of the pump motor. The water level sensor should be placed in the tank. If the water level is too low for the pump to work, the sensor will signal to the inverter to stop the pump.

Similar to the water supply system, the wastewater tank is also equipped with sensors that detect and control the level of sludge and the presence in the tank.

Understanding and choosing a water pump system carefully is extremely important. For buildings, two solutions are always the top priority: high-pressure water pumps and booster water pumps.

High push water pump is a type of machine capable of pushing water from the underground water source up through the energy source converted from electricity. High thrust water pumps have much higher capacity than conventional pumps.

High push water pump

The structure of high push water pump

High-pressure water pump is compact and convenient. Besides the main parts such as the motor and pump head, the machine also has a pump chamber cover, anti-friction pump disc with high heat resistance, thereby, helping the water flow stably. In addition, high thrust pumps are equipped with sensor relays. This part helps the machine automatically cut off the power when the temperature is too high, avoiding overheating, causing fire and explosion. Moreover, the machine also has a high-precision motor rotating core that is plated against rust to increase the durability and life of the machine.

Types of high push water pump

Booster water pump is also known as booster water pump. This type of water pump has the function of increasing the water pressure automatically in the pipeline when the pressure decreases. The machine is capable of delivering a much larger volume of water than a conventional water pump in the same operating period.

Booster water pump

The structure of booster pump

The booster pump mainly consists of two main parts, the pump body and the pressure tank. Besides, the machine also has other auxiliary parts such as pressure switch, suction inlet, outlet, base and power cord.

Types of booster water pump

Standards for installation of domestic water pumping systems

With the goal of bringing the best quality service to customers, Taisei VN not only provides management - operation services, we also cooperate with other reputable units in ware pump maintenance for the building. When in-depth consultation and intervention is needed, Taisei VN will invite specialized units for each system to evaluate and offer the most suitable solutions. During the implementation process will be deployed under our close supervision to ensure your assets are safe.

----------------------------------------------

Contact information

Taisei VN

Address: P.1901 Saigon Trade Center, 37 Ton Duc Thang, Ben Nghe Ward, 1 District, Ho Chi Minh City

Hotline: 0911 401 955

Email: cs@taisei-bm.com.vn

LinkedIn: https://www.linkedin.com/company/taisei-vn/

Facebook: https://www.facebook.com/taisei.com.vn